Needle probe load curve

Needle ProbeProduct Specifications

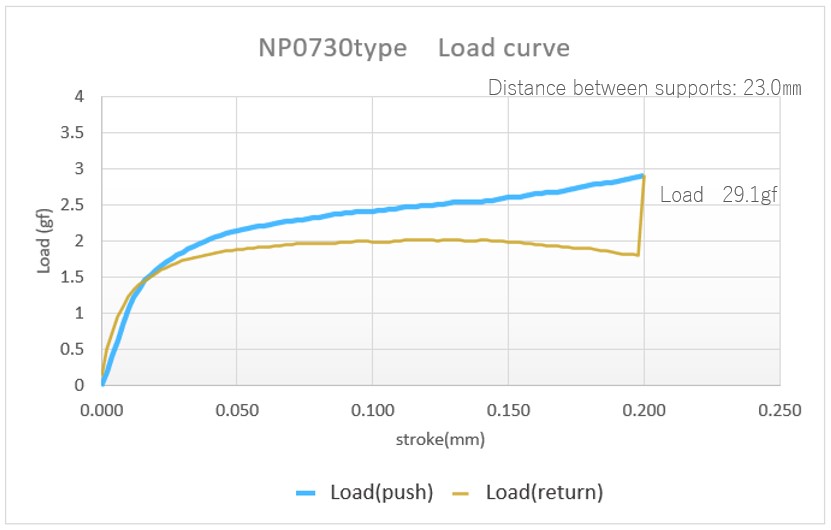

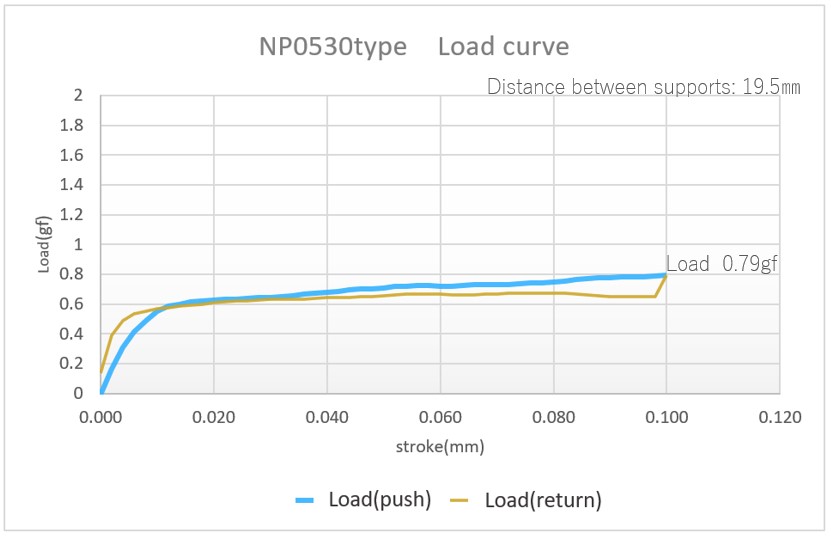

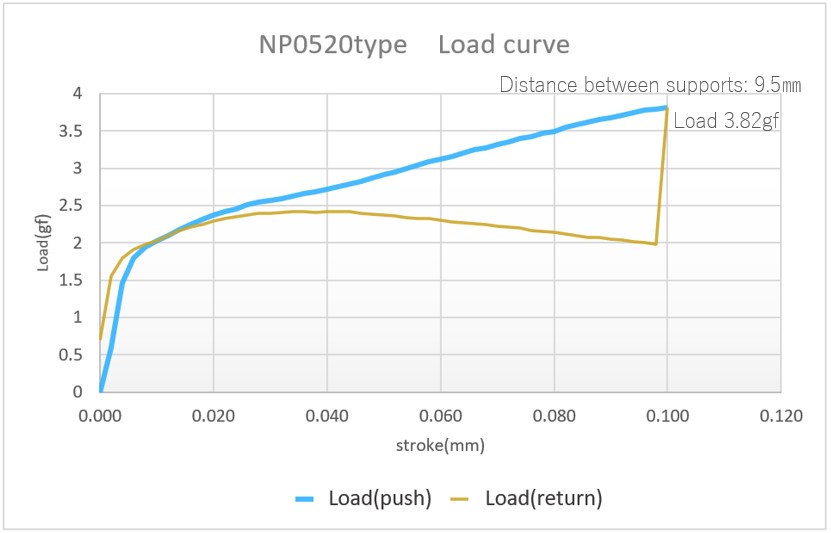

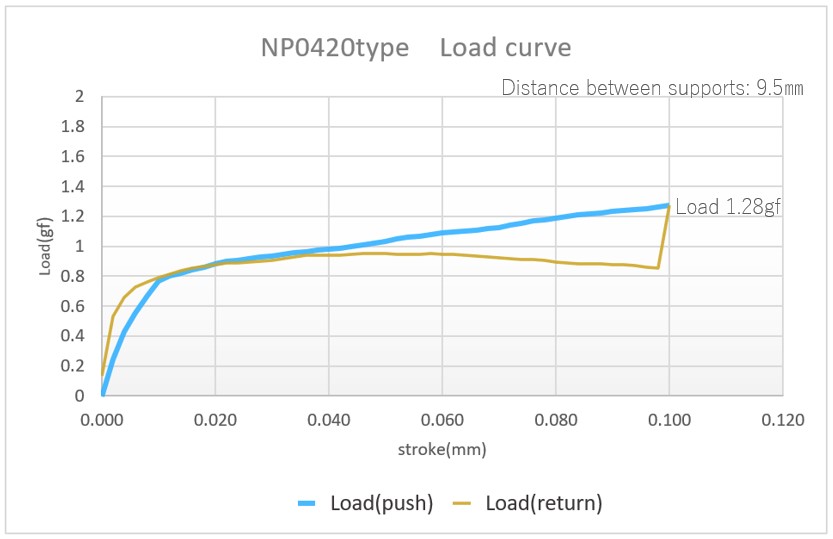

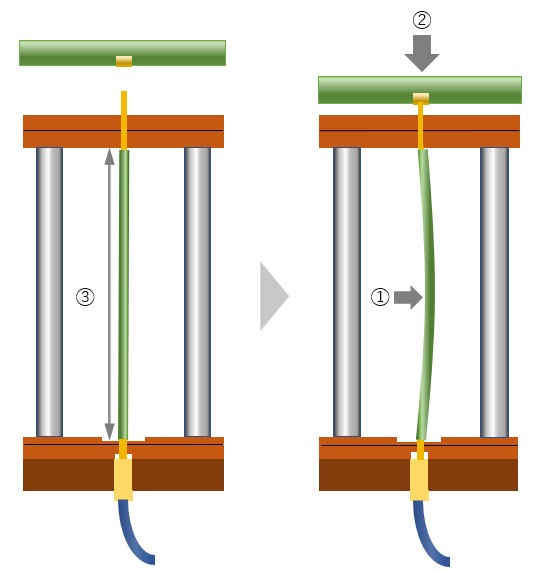

What is the load change due to the stroke of the needle probe?

It depends on the jig structure and the needle probe used.The following are typical types of load curves.

<Needle probe load curve>

At the same distance between the supports, the thicker diameter of the needle probe, the higher the load.

The NP0520 type and NP0420 type above have the same distance between the supports, but there is a difference in load due to the difference in wire diameter.

Distance between supports: 9.5mm 50μm 3.82gf, 40μm 1.28gf

If the contact pressure to the product is insufficient or the contact is unstable, shorten the distance between the supports points or change to a thicker wire diameter to increase the load.

Problems such as the fact that the load is already high and you want to reduce the contact marks of the product, or that the product is distorted by the load, can be solved by increasing the distance between the supports or by reducing the wire diameter and setting the load lower.